Why Early Planning and Value Engineering Is the Smartest Investment in Your Next Commercial Build?

A successful commercial build rarely comes down to one "big" decision. Instead, it's the accumulation of smart, early choices, made before drawings are finalized and materials are ordered, that determines whether a project stays on schedule and on budget.

If you're working with a commercial general contractor in Waco, the best outcomes typically start long before mobilization. Early planning and value engineering help teams anticipate cost drivers, spot constructability issues, and align the design with real-world constraints in Waco and greater Central Texas, where labor availability, permitting timelines, and weather can all affect delivery. In the blog, we will discuss why early planning and value engineering are key to getting the best bang for your buck in Waco, Texas.

What "Early Planning" Really Means in Commercial Construction?

Early planning is the structured work that happens before construction documents are complete and before bids are locked. It's when the owner, architect, engineers, and general contractor for commercial project execution align on scope, schedule, budget, and risk.

This phase often includes programming, site evaluation, preliminary budgeting, phasing strategy (especially for occupied facilities), and permit pathway mapping. In Waco and McLennan County, early coordination can prevent delays tied to plan reviews, utility coordination, and site-specific civil requirements.

For owners comparing a general contractor in Waco, TX, early planning is a major differentiator because it shifts decisions from "reactive fixes" to "proactive controls." The earlier you make a decision, the cheaper it usually is to change.

Local Factors That Make Early Planning Even More Valuable in Waco, Texas

Waco, Texas, projects face variables that can surprise teams that plan too late. These aren't to worry, they're reasons to plan with intent.

Regional weather swings that affect concrete pours, exterior work, and site access

Lead-time volatility for HVAC units, switchgear, storefront systems, and specialty finishes

Trade availability fluctuations across Waco and the nearby Texas region

Site constraints (stormwater, access, soil conditions) that change civil costs quickly

When preliminary planning services in Texas are done thoroughly, these variables become manageable inputs instead of costly disruptions.

Value Engineering: More than "Cutting Costs"

Value engineering is a disciplined method for improving value, often defined as a function divided by cost, without compromising performance, durability, or code compliance. Done well, value engineering protects the intent of the project while refining how that intent is delivered.

Value Engineering is not just about getting cheaper material. In fact, value engineering may recommend drastic changes to systems, sequencing, structural approaches, or layouts that might lead to reduced labor hours, shortened schedules, or lower lifecycle costs.

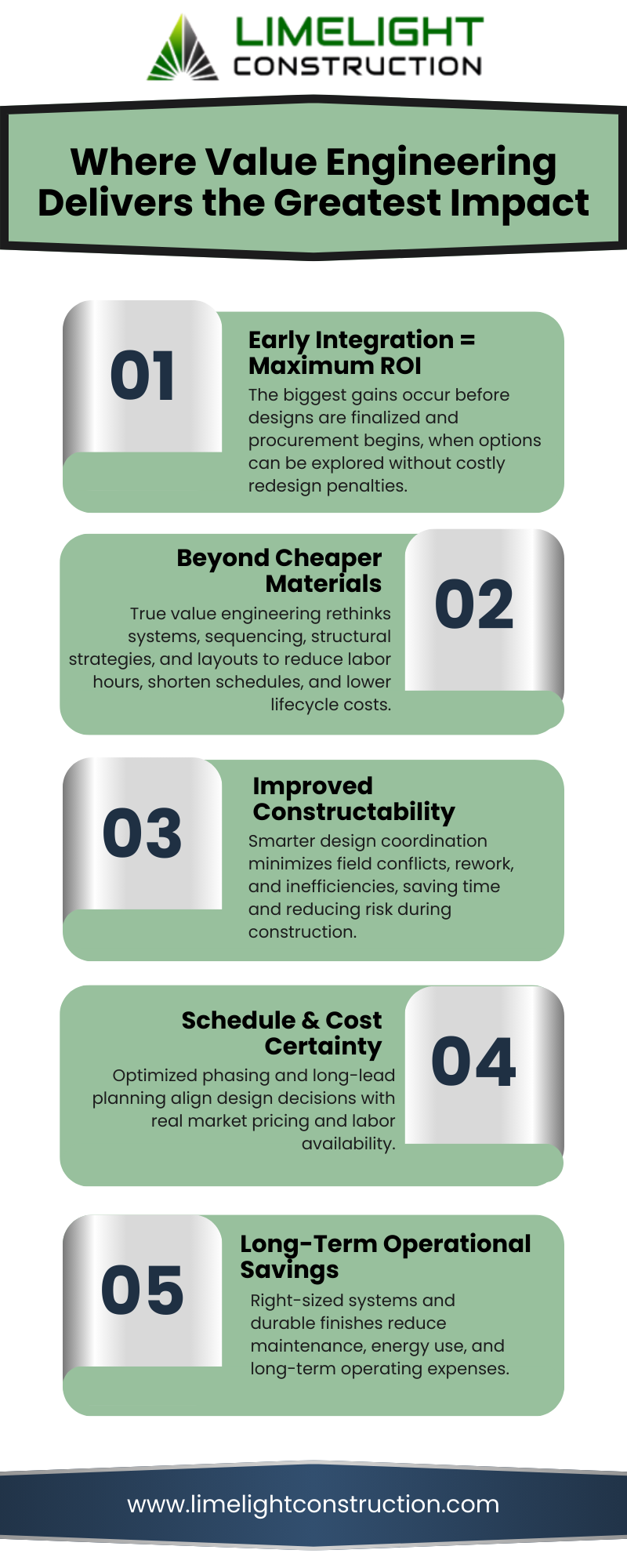

Where Value Engineering Creates the Biggest Returns

Value engineering leads to maximum ROI when it is integrated early, before the design hardens and before procurement begins. At that point, the team can still explore options without redesign penalties.

Value Engineering is not just about getting cheaper material. In fact, value engineering may recommend drastic changes to systems, sequencing, structural approaches, or layouts that might lead to reduced labor hours, shortened schedules, or lower lifecycle costs.

Value engineering often delivers benefits in these areas:

Constructability improvements that reduce field conflicts

Schedule compression through smarter phasing and long-lead planning

Cost certainty by aligning design with market pricing and labor realities

Long-term operating savings through right-sized systems and durable finishes

Owners who treat value engineering as a partnership process, not a last-minute trim exercise, typically avoid the painful 'late redisign cycle.'

How Early Planning Reduces Change Orders and Schedule Drift

Change orders usually come from four sources: incomplete scope definition, conflicts between drawings and field conditions, late selections, and unforeseen site/permit requirements. Early planning attacks each source directly.

When a general contractor in Waco, TX, is involved early, the team can run constructability reviews and coordination checks that flag issues before they become field rework. That's especially important in commercial spaces with dense mechanical, engineering and plumbing systems, specialty equipment, or tenant-specific requirements.

Early planning also strengthens schedule reliability. If the team identifies long-lead items early, procurement can begin on time, preventing downstream delays that often cascade into overtime and acceleration costs.

A Practical Checklist: Early Planning and Value Engineering Steps That Pay Off

Use this checklist as a simple roadmap before you finalize design and pricing. It also helps you evaluate any commercial general contractor in Waco during early conversations.

Confirm project goals and constraints (budget, opening date, phasing, critical features)

Validate the site (utilities, access, drainage, geotech assumptions, easements)

Establish a realistic preliminary budget with allowances tied to selections and lead times

Run a constructability review of the early drawings

Identify long-lead items and set procurement decision deadlines

Complete a value engineering workshop focused on function, lifecycle, and schedule

Align permitting and inspection milestones with the construction schedule

Lock scope priorities so late changes don't determine cost and timeline

If you do only one thing, do this: document decisions early, and keep them visible to the entire team. Hidden assumptions are one of the fastest ways budgets drift.

What to Ask Your Contractor before You Move Forward

Early planning works best when everyone shares the same definition of "done" and the same tolerance for risk. Ask direct questions and expect direct answers.

Consider asking:

How do you handle preliminary planning services in Texas? What's included, and what's not?

What value engineering process do you use, and how do you document options and trade-offs?

How do you forecast lead times and market pricing for key scopes?

How do you minimize change orders, contractually and operationally?

These questions apply whether you're selecting a general contractor for commercial project delivery or comparing firms across Central Texas.

Final Words

If you're planning to undertake a commercial construction process, the ideal thing to do is plan ahead and employ techniques that may lead to reduced costs. Planning early and value engineering can not only save you a lot of money, but it can also avoid local issues that may lead to delays or increased costs.

If you are planning to hire a local and reliable commercial general contractor in Waco, TX, check out Limelight Construction for all your commercial construction needs.

FAQs

1. What is value engineering in commercial construction?

Value engineering is a structured process that improves value by maintaining required performance while reducing unnecessary cost, complexity, or schedule risk. It can involve materials, systems, layouts, procurement timing, or sequencing, not just "cheaper" or " substitutes."

2. When should I start early planning for a commercial build in Waco?

Start as soon as you have a site and a rough concept, even before final design. Involving a commercial general contractor in Waco early helps identify cost drivers, permitting considerations, and long-lead items while changes are still inexpensive.

3. Does value engineering reduce quality?

It should protect the project's goals and code requirements while removing waste or improving constructability. Poor VE is last-minute cost-cutting; effective VE is early, documented decision-making.

4. How do early planning services help control change orders?

They reduce the leading causes of change orders: unclear scope, drawing conflicts, late selections, and unforeseen site or permitting issues. Early planning clarifies assumptions and aligns the team before construction begins.

5. Are early planning principles useful for remodels or residential projects, too?

Yes. While commercial projects have different compliance needs, the discipline carries over. That's why topics like best remodeling contractors in Waco and best custom home builders in Waco, TX, often overlap with planning: early scope definition and VE-style trade-off decisions reduce surprises.